The Archimbaud Group, is a family-owned sawmill originally specializing in the manufacture of pallet boards. To gain value from their co-products (sawdust and shavings), the group has developed wood pellet production units for heating purposes.

The Archimbaud Group has selected S3d Ingénierie to design and commission a demonstration unit to produce hydrogen from its wood pellets. The aim is to reduce the group’s energy footprint by producing hydrogen for mobility purposes. The hydrogen can be sold to the French distribution network or used to fuel the company’s future trucks. Under ISO 14687 or SAE J-2719, fuel purity for ground transportation must be 99.97%.

Hydrogen for fuel cells – Purity is paramount

Hydrogen, when used for fuel cells, must be ultra-pure. Under ISO 14687 or SAE J-2719, fuel purity for ground transportation must be 99.97%. Any impurities in the hydrogen supply can harm the fuel cells, so it’s crucial to guarantee purity throughout the processing and delivery stages to reduce the risk of damage, non-compliance, and disruption in fuel delivery.

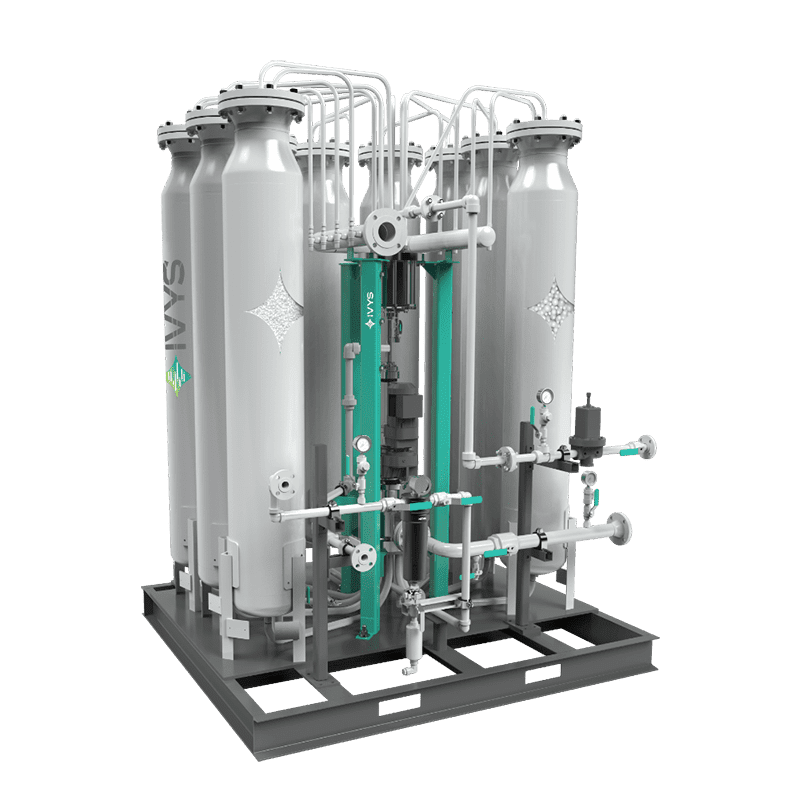

Hydrogen purification by Pressure Swing Adsorption System (PSA)

To meet the mill’s requirements, S3D selected a pair of Ivys’s H3200 PSA systems to purify the hydrogen produced from wood pellets. The pair will run as a series, with the first removing most of the bulk of contaminants and the second polishing the hydrogen to an ultra-high purity.

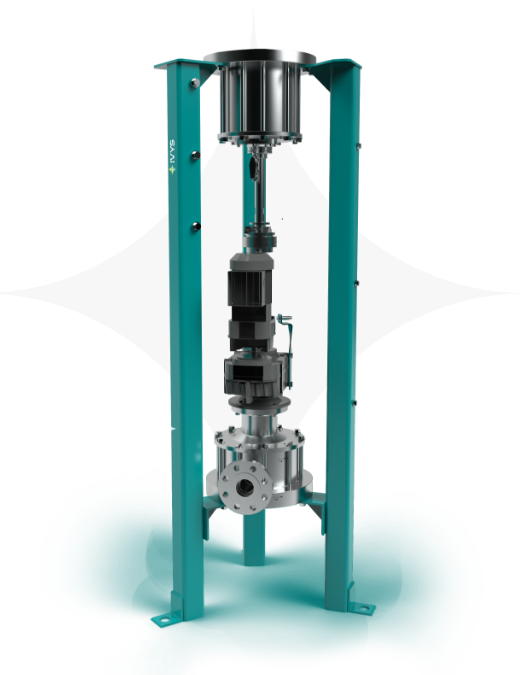

Ivys’s PSA system utilizes a multi-bed pressure swing adsorption (PSA) technology to ensure dependable hydrogen purification for fuel cells. The unique rotary valve, designed with simplicity and elegance, is durable and reliable. It surpasses purity standards by providing purity levels of up to 99.9999% and has an availability of over 99.5%. In contrast to other PSA or membrane systems, Ivys’s PSA system has a smaller footprint due to its compact size. It is highly energy-efficient, with a power rating of 0.25 – 1Kw. The PSA system has adaptable capacity, with a 100-40% turndown range. The units are quickly commissioned as they are skid-mounted. They are user-friendly and do not require specialized training to operate. Ivys’s PSAs come CE-certified, which provides assurance that the units meet the EU safety, health, and environmental protection requirements.

The on-site commissioning of the pair of H3200 PSA units began in January 2025. Ivys’s Testing and site support technician, Frédérick Tremblay, was on location to complete the installation, testing, and commission of the units.

Revisit this page for more project updates as production begins.

France’s Hydrogen production targets

France aims to reach a production capacity of 6.5 gigawatts of low-carbon electrolytic hydrogen by 2030, with plans to increase this to 10 gigawatts by 2035. In support of these efforts, the government has pledged to invest nearly €9 billion by 2030 to facilitate the adoption of decarbonized hydrogen. This initiative illustrates France’s commitment to advancing sustainable energy solutions and accelerating the transition to a sustainable, low-carbon economy.

Ivys is proud to support France’s energy transition by designing, manufacturing, supplying, and supporting the operation of gas-purifying systems. Our PSA technology is being used in various sites across France.