FAQ – Pressure Swing Adsorption Systems (PSA)

Here is a list of the frequently asked questions about our PSA system.

How does a PSA work?

A PSA or Pressure Swing Adsorption System works on the principle of preferential “adsorption” or adhesion of certain gas molecules onto a solid adsorbent material under pressure, and the reversible nature of the process to release the adsorbed molecules at low pressure.

Pressurized feed gas is introduced to a vessel filled with adsorbent and the gas stream is purified as certain molecules are adsorbed onto the material inside the vessel. The “purified” product gas flows from the top of the vessel at pressure. Once the vessel has reached its adsorbent capacity, the gas flow is “switched” to a fresh column and the pressure is reduced in the loaded vessel to release the adsorbed molecules at low pressure as “exhaust” gas, thereby regenerating the adsorbent for another cycle. This process is fully reversible and repeats itself to provide a continuous flow of purified gas. Multiple beds are used to allow for near continuous process flows.

How is the PSA controlled?

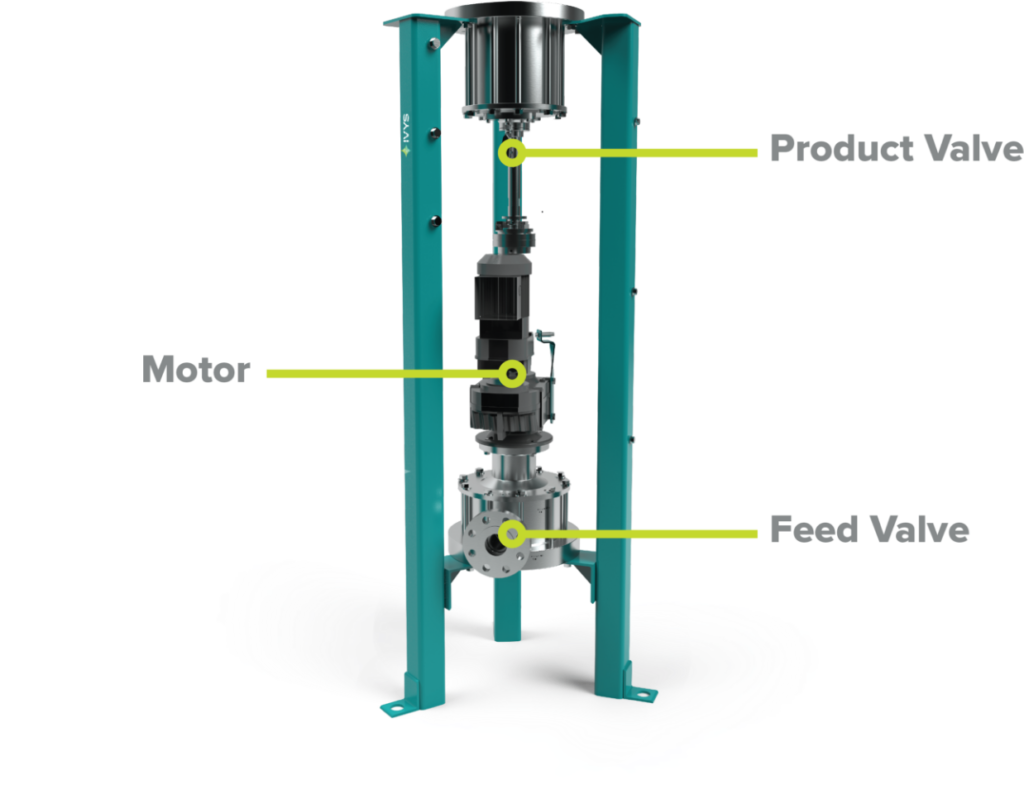

The operation of the PSA is controlled by pressure and cycle speed to achieve the desired flow and purity. Gas flows in Ivys’ PSA are controlled by a set of rotary valves rather than the on-off switching valves found on a conventional PSA system. The rotational speed of the rotary valves is controlled by an analog signal from a PLC (Programmable Logic Controller) to the variable speed drive motor which turns the rotary valves. Operation, turndown, and product gas purity control are achieved by adjusting only the rotary valve rotational speed.

What is the maximum turndown?

The maximum turndown is typically 40%. However, in some installations, Ivys has provided capacity turndowns to below 25% of maximum design capacity.

How do the rotary valves work?

The PSA has one rotary valve (feed valve) connected to the bottom of each bed and one rotary valve (product valve) connected to the top of each bed. Feed gas is allowed to flow through a passage in the feed valve to at least one bed while, at the same time, purified product gas is allowed to flow from the bed through the product valve passage to the product line. Other flows are similarly connected through the rotary valve for exhaust, purge, equalizations, etc.

As the two valves rotate together, gas flows are gradually switched from one bed to the next to produce the efficient Ivys’ PSA cycle. Although this cycle is much faster than conventional PSAs (with the inherent advantages), this is still a very slow rotational speed of 1.0 to 0.3 RPM (Rotations Per Minute)

How is purity measured and controlled?

The PSA Operator normally provides the gas analysis equipment needed to measure and monitor PSA product purity going to their customer depending on their specific needs (i.e accurary, frequency, and what components to analyze). The PSA is commissioned to operate at the unit’s design purity at the time of its performance test, including any turndown operation points. If conditions during ongoing operation change more than the 2.5% specified, adjustment of the PSA cycle speed may be required. In certain situations, an online gas analyzer with a proportional output signal can be used as a control loop input signal to automatically adjust the PSA cycle speed depending on measured purity. This is best deployed when the feed conditions are expected to change frequently and the measuring instrument is well within its detection and drift limits.

What kind of adsorbents do you use?

Ivys uses many different types of commercially available adsorbents such as activated alumina, silica gel, zeolites, and carbon materials. The type and amount of each adsorbent is selected for your specific application and conditions as determined by our process engineers using advanced process models for Ivys’s specific Fast Cycle PSAs.

What is the life expectancy of the adsorbents / what can damage the adsorbents?

PSA adsorbents have been in operation without degradation in many cases for the life of the plant. Adsorbents can be damaged through mis-operation such as excess gas flows which “lift” the material causing attrition and breakdown of the beads. Also, liquids of any kind can strongly adhere to the adsorbent and reduce its working capacity.

What levels of contamination can the PSA tolerate (H2O, VOCs, H2S, etc.)?

The level of contaminants the PSA can tolerate depends on the components in question and the specific application. Please provide a list of contaminants, with the typical concentrations of each, to a Ivys Specialist to review. Examples of gas components that can lead to contamination include high levels of H2S, strong acids, high molecular weight hydrocarbons, etc. The PSA is designed to operate with gas streams saturated in water, but liquid water should be removed prior to the PSA.

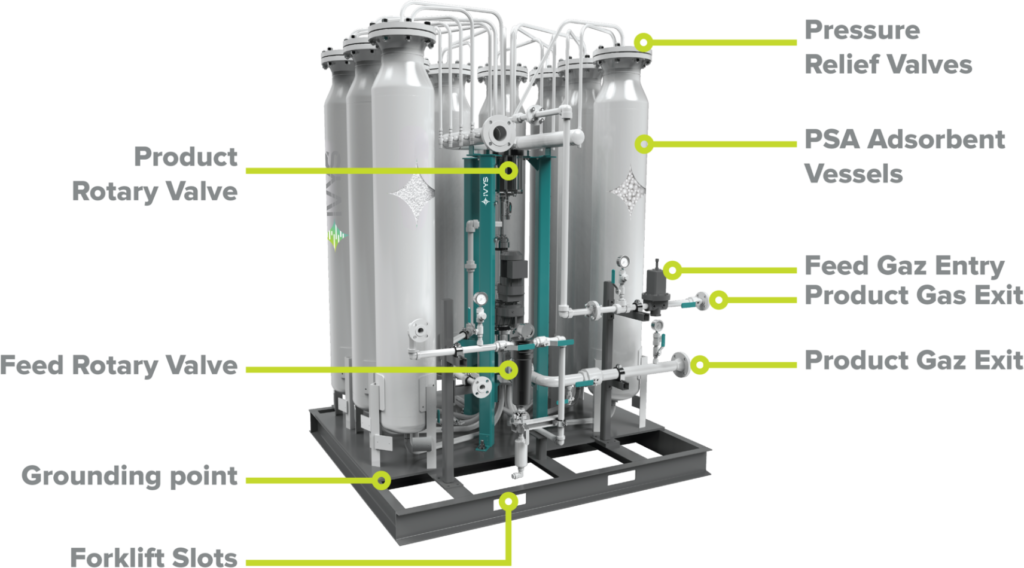

What safety or protective systems do you supply with the PSA?

Ivys uses a HAZOP (Hazard and Operability) study method to identify and address risks associated with our systems. A gradual feed pressurization control prevents the adsorbent from being lifted during re-starts; a feed coalescing filter protects the rotary valves and the adsorbent from liquids and particulates and safety relief devices on each bed protects the plant for a fire case safety relief.

What is the system reliability?

Ivys’s PSAs have accumulated over 15,000,000 commercial operating hours (over 30,000,000 valve hours), with more than 200 plants in continuous duty. The rotary valves are highly reliable, with recommended service intervals of 5 years, and an inspection at 2.5 years. Ivys’s PSA installations have proven availabilities beyond 99.9%.

How long does commissioning take?

Commissioning of an Ivys PSA typically takes between 3 and 5 days for small systems and 1 to 2 weeks for larger installations.

What about spare parts and other consumables?

Other operating consumables include feed filter elements and gear motor oil changes once every 2-3 years. Rotary valve seals typically will be replaced every 5 years.

How can I tell if there is a problem with the rotary valves?

Ivys’s rotary valves are highly robust and have undergone rigorous quality testing before leaving Ivys’ facilities. In the unlikely event that the rotary valves stop turning, an alarm will be triggered. This may be due to a power outage, drive or motor fault, or high torque at the valves. Of the few faults of this nature, the power supply or drive issues have been resolved, allowing normal operation to resume without requiring Ivys field support service. If rotary valve leakages should occur, the PSA would experience a lower-than-expected product gas recovery. However, product gas purity would be maintained so plant operation is not interrupted. Monitoring will allow operating staff to trend performance and schedule Ivys inspection/service at a convenient time.

Can the product gas become contaminated?

Our rotary valves are designed to ensure that rotary valve leakage does not contaminate the product gas. Additionally, if the PSA is suddenly shut down, there is no rotary valve position that would permit product gas contamination. When the PSA is purged with inert gas for maintenance or an extended shutdown, Ivys’s standard start-up procedures prevent contamination of the inert gas with the product gas.

Can particulates be present in the product gas?

As with most gas processing equipment, small particles may be present in the product line during initial start-up, but they are not generated during normal operation of the PSA.

How can I tell if the PSA adsorbents are degraded?

Typically, PSA adsorbents will last for the life of the plant. However, if the PSA operates under conditions where flows or contaminants significantly exceed the unit’s design parameters, the adsorbents can become deactivated, resulting in a loss of product gas recovery and/or capacity observed.

Are there any hazardous materials in the PSA?

Most PSA systems do not contain hazardous materials. An MSDS (Material Safety Data Sheet) accompanies the IOM (Installation, Operation and Maintenance) manual for every Ivys PSA.

What electrical power requirements are necessary?

The PSA can be configured to handle various power sources. Our standard electrical power requirements are 120 VAC/1 ph/60 Hz, 230/400 VAC/3 ph/4 wire/50 Hz, or 200 VAC/3 ph/3 wire/50 Hz for the PSA motor. For instruments, we generally require 120 VAC/60 Hz 1 ph, 220 VAC/50 Hz/1 ph, or 110 VAC/50 Hz/1 ph, with some instruments needing low voltage DC power, typically sourced from a PLC/DCS source.

What if gas conditions change or I want to operate at different product purity levels?

Once the PSA cycle is tuned at the time of commissioning, the cycle speed can be re-programmed or adjusted to the desired level of product purity, even with a different feed gas composition. If operating conditions change drastically (i.e. feed pressure changes), the PSA may require re-tuning by Ivys for the new conditions.

What signals do I need to send to the PSA?

The signals required to operate Ivys’ PSA include a 4 to 20 mA signal to the variable speed drive for the rotary valve motor, and signals to the instruments included on the PSA. Typical Ivys PSA installations require no more than 10 I/O signals.

What is the PSA’s start-up time?

The typical start-up time for pressurizing a Ivys PSA is 15 minutes. Under normal start-up conditions product purity is achieved once pressurization is complete. Restarts can be considerably shorter.

What happens after an emergency stop of the PSA?

After an emergency stop, the motor to the PSA stops and the feed and product isolation valves close. The PSA remains under pressure and the adsorber beds are stopped within their bed cycles. After the resolution of the emergency stop, the PSA is re-started and the unit resumes normal operation at the point where it stopped. If the E-stop lasts for more than an hour or two, the system should be de-pressurized per Ivys shutdown procedure to remove residual contaminants.

Can the PSA operate outdoors?

The PSA is designed for outdoor operation with a protection rating of IP53 or better. The design operating ambient temperature is from 4 to 48°C (40 to 118°F). For more extreme environments, a cold weather option (heat tracing with insulation) can be included to allow operation at ambient temperatures as low as -40°C.

What feed and exhaust pressures should be used for best performance?

This will depend on specific conditions but, generally, lower exhaust and higher feed pressure will improve performance and reduce PSA size. Typical conditions for feed pressure range from 4 barg to 27 barg with as low an exhaust pressure as possible.

Do you have a question that is not addressed?

Contact us and we’ll be in touch.