Compressed Air Systems Audit: Cut Your Energy Costs by 40%

In an era where energy costs weigh heavily on manufacturers’ bottom line, optimizing compressed-air systems emerges as a powerful opportunity for financial returns. Through a targeted audit – such as the SCADAR service by IVYS – you uncover hidden losses, slash your energy bills, and maximize equipment profitability.

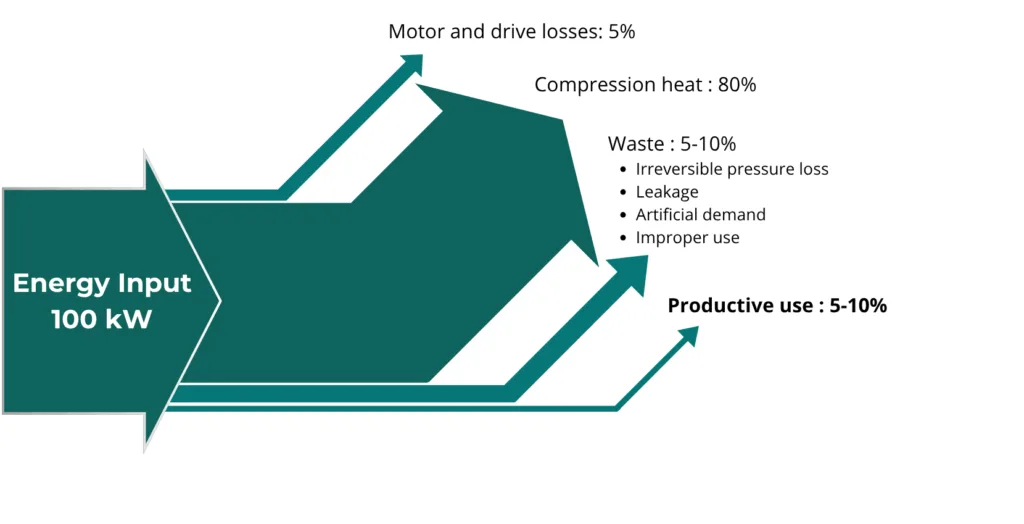

Industrial compressed‑air systems are often silent yet critical utilities: essential for production, but notoriously inefficient. Estimates indicate these systems consume up to 10 % of total industrial electricity (lasc.endress.com). Even more striking: as much as 90 % of the input energy may be lost through leaks, heat, and poor configuration (Natural Resources Canada).

Therefore, auditing a compressed‑air system is no longer simply “good housekeeping” – it’s a strategic project: cost reduction, enhanced reliability, and a tangible step towards zero‑carbon operations. In this article, we present the current state, analyse the real challenges, then offer IVYS’s strategic vision for going beyond the audit with a forward‑looking industry perspective.

Substantial Financial Losses

The data speak clearly: compressed‑air systems are among the most energy‑inefficient assets in industrial plants. For example:

- One study reported that when losses from compression, leaks, and distribution are factored in, the useful work at the end‑use may only be 5 % – 10 % of the electrical input (osti.gov).

- According to Endress+Hauser, “up to 10 % of industrial electricity consumption is used to produce compressed air and 95 % of that energy may be lost as waste heat or leaks” (apsc.endress.com).

- Additional research identifies that leaks alone may account for 20 % – 40 % of total air consumption when systems are poorly maintaine (ORDNUR).

- Audits demonstrate tangible results: one study reports energy consumption reductions exceeding 40% following leak repair and equipment optimization (Natural Resources Canada).

- For one industrial client we worked with, a $2,500 audit investment yielded $3,297 in annual savings, achieving full payback in under 10 months.

Compressed air audits thus represent a strategic lever for energy performance and competitiveness that is all too often overlooked.

Analysis of the issues

1. Technical and operational obstacles

Despite the potential, several obstacles hinder industrial optimisation:

- Leaks: ubiquitous, often invisible, and regularly underestimated. Even a small leak can lead to thousands of dollars in annual energy waste.

- Over‑pressure or unnecessarily high system margins: elevated distribution pressure increases losses and diminishes system efficiency (Natural Resources Canada).

- Poorly dimensioned or oversized compressors/tubing: when equipment runs at low load or a large buffer is built “just in case”, efficiency drops.

- Lack of data and monitoring: without proper instrumentation, visualising and controlling system performance is challenging.

2. Strategic implications for industry

Air compressor optimization addresses key strategic concerns for your business:

- Reducing fixed costs: In a context of volatile energy prices, optimizing your electrical consumption protects you against rate increases and directly improves your profit margins.

- Decarbonisation: As highlighted in “The Overlooked Carbon Cost” article, inefficient compressed‑air systems hinder net‑zero goals since higher electrical consumption means higher Scope 2 emissions (Industrials Machine).

- Reliability and productivity: Pressure fluctuations, unaddressed leaks or insufficient capacity can disrupt operations.

- Competitiveness: In cost‑pressured industrial sectors, the ability to reduce fixed utility costs distinguishes winners from laggards.

- Regulatory and subsidy drivers: Incentive programs (such as those from Hydro‑Québec in Québec) support audits and implementation of energy‑efficient measures.

3. Positioning the audit in the value chain

Carrying out an audit is a first step, but the ambitious view is to treat optimisation as an integrated project:

- Data collection (pressure, flow, power, temperature) over several days (mirroring the SCADAR methodology)

- Data‑driven analytics via a digital platform

- Clear, actionable recommendations

- Follow‑up: implementation, monitoring and continuous improvement

“At IVYS, we view compressed air system optimization not as a one-off service but as a profitable investment that generates measurable savings year after year.”

Daniel Routhier, Director of Sales & Business Development – Compressed Air

Innovation & digitalisation

Our SCADAR audit is powered by on‑site sensor installation, data collection over time and a visual analytical portal:

- Pinpointing leaks, identifying over‑pressure, assessing system performance

- Modelling savings scenarios (dollars, kWh, tCO₂) and calculating your return on investment via advanced simulation

- Delivering a roadmap of improvements with business case and environmental metrics (as demonstrated in your newsletter)

Implementation and support

Our offering goes beyond audit: we support clients through the entire project lifecycle – audit, grant application, implementation and post‑audit monitoring. The aim is rapid payback (often < 12 months) and sustainable performance.

Future implications

Looking ahead, several key developments will directly impact industrial compressed‑air systems:

- Continuous energy efficiency: Audits are no longer one‑time actions; they serve as the starting point for ongoing improvement. With real‑time sensors and monitoring, companies can immediately detect losses, optimize energy use, and extend compressor lifespan.

- Predictive maintenance and digitalization: Monitoring technologies allow maintenance needs to be anticipated before issues occur. This reduces downtime, lowers repair costs, and ensures stable production.

- Available incentive programs: Governments offer financial incentives for energy efficiency projects. Companies that optimize their compressed-air systems today can recover a significant portion of their investment through these support programs.

- Reliability and competitiveness: In a cost‑pressured industrial market, maintaining reliable production while lowering energy costs becomes a tangible competitive advantage. Optimized systems are a strategic performance driver.

Investing in optimization today ensures sustainable savings, stable operations, and a strategic edge for tomorrow.

Optimizing industrial compressed air systems is far more than a cost-cutting exercise—it’s a strategic investment that improves your profitability and competitive edge. At IVYS, we firmly believe that every kilowatt-hour saved translates directly into dollars in your pocket. By launching a SCADAR audit today, you reduce your energy bills, improve production reliability, and free up capital to reinvest in your growth.

Let’s transform your energy waste into measurable profits.

Ready to unlock your savings potential? Discover our SCADAR compressed air audit service.