By Ivys for INL Communications.

Ivys Energy Solutions and Ivys Adsorption are teaming up to provide Idaho National Laboratory (INL) with a complete hydrogen compression, purification, storage and vehicle fueling solution as part of the (SOEC) Hydrogen Post-Processing and Coach Fueling Demonstration project. This is a first-of-its-kind demonstration of core technologies and products that support key aspects of the national Hydrogen Hub program.

Project goals and objectives

Like many other organizations, INL is taking concrete steps to reduce its carbon emissions and become net zero by 2031. One project supporting this goal is its (SOEC) Hydrogen Post-Processing and Coach Fueling Demonstration project.

This pilot project aims to limit risk and validate large-scale, grid-tied solid oxide electrolysis (SOEC) hydrogen production technology while converting their coach fleet toward zero emission. An objective of this project is to support the initiatives of the U.S. H2 Hubs Program. H2Hubs, an $8 billion hydrogen hub program established through the Bipartisan Infrastructure Law, will establish the building blocks of a nationwide clean hydrogen network that will significantly aid in decarbonizing various sectors of the economy, including heavy industries such as steel and cement production and heavy-duty transportation.

INL is evaluating SOEC hydrogen generation for two applications. The first is feedstock, which uses hydrogen as a commodity for greening various non-mobility sectors. The second is as an energy carrier for stationary fuel cell power generation and mobile fuel cells for the transportation sector.

INL manages a fleet of more than 90 coaches to transport staff members and visitors around its 890-square-mile campus. This fleet provides the lab with the opportunity to use hydrogen gas, generated through SOEC systems, as fuel for fuel cell-powered coaches.

This project will serve as a demonstration and proof of concept for other fleet owners who want to use hydrogen-powered fuel cell electric vehicles (FCEVs). It will also reduce carbon emissions from these vehicles and align with INL’s net-zero plan.

This project’s ultimate aim is to assist the industry in achieving SOEC hydrogen production at a cost of $1 per kilogram at the megawatt scale. Through this project, INL aims to create dependable, safe designs and operating procedures for post-processing gases from SOEC systems greater than 100 kW. The project includes installing and commissioning a hydrogen refueling station.

The INL (SOEC) Hydrogen Post-Processing and Coach Fueling Demonstration project will capture all product hydrogen from a high-temperature steam electrolysis (HTSE) system connected to INL’s 500 kW test facility and process it as fuel for fuel cell electric vehicles. This project will demonstrate the pressurization, purification, storage, and dispensing of hydrogen gas from SOEC systems. It will focus on developing safe hydrogen post-processing for 100+ kW SOEC systems (2.7+ kg-H2/hr) to reduce risk to future regional hydrogen hub projects.

Our Solution

To meet all the project requirements and address its technical and operational challenges, Ivys Adsorption and Ivys Energy, worked together to offer a comprehensive solution. Together, the Ivys family of companies are uniquely positioned to address the needs of the project with deep expertise in hydrogen processing, purification, and refueling systems.

The solution encompassed the following systems and services.

- A Hydrogen Upgrading System to take the output gas stream from the SOEC and deliver high-purity hydrogen.

- A Hydrogen Refueling Station that manages all aspects of compression, storage, and dispensing of the upgraded H2 stream.

- System integration and installation ensuring compatibility with the upstream H2 supply, the hydrogen fuel cell vehicles, and site needs.

Challenges in Hydrogen Processing and Fueling

With any project at this scale, several key challenges must be addressed. For the (SOEC) Hydrogen Post-Processing and Coach Fueling Demonstration project, the technical and operational challenges can be summarized as follows:

Hydrogen Purity

Hydrogen purification is a key concern for a wide range of feedstock, energy, and mobility applications. Any contaminants present in the hydrogen supply can impact the downstream process, making it essential to ensure purity is obtained and maintained during the hydrogen processing and delivery processes to minimize the risk of damage, non-compliance, and fuel delivery disruption.

Hydrogen FCEVs (including industrial, light, medium, and heavy-duty vehicles) are among the most stringent applications. Under SAE J-2719, fuel purity for ground-level vehicles must be 99.97 mol% H2 with no more than 300 µmol/mol of any one non-hydrogen gas, along with much stricter requirements for some applications.

Low-Pressure Variable Hydrogen Sources

Many of the hydrogen sources being developed and deployed today and as part of the Hydrogen Hub program produce low pressure gas at flow rates that can change dramatically due to electrical load following or feedstock variations. The ability to accept this input gas and seamlessly produce pure output gas at useful pressures is critical to unlocking the value of hydrogen generation technologies.

Benefits of the Ivys Approach

The combined Ivys Adsorption and Ivys Energy Solutions team brings a comprehensive portfolio of innovative technology and experience to address challenges like the above in the evolving hydrogen market.

Hydrogen Upgrading

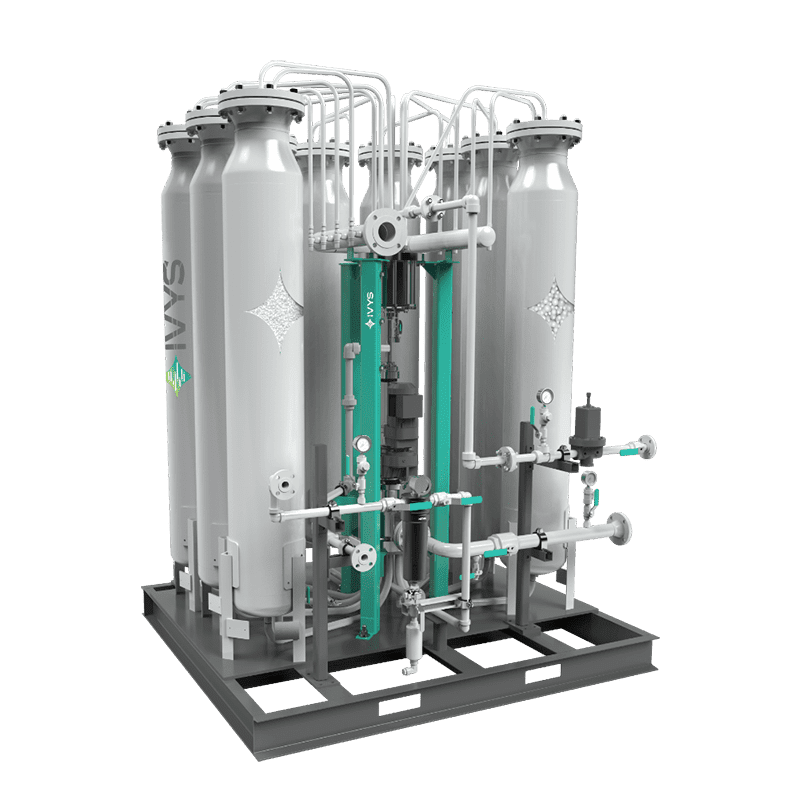

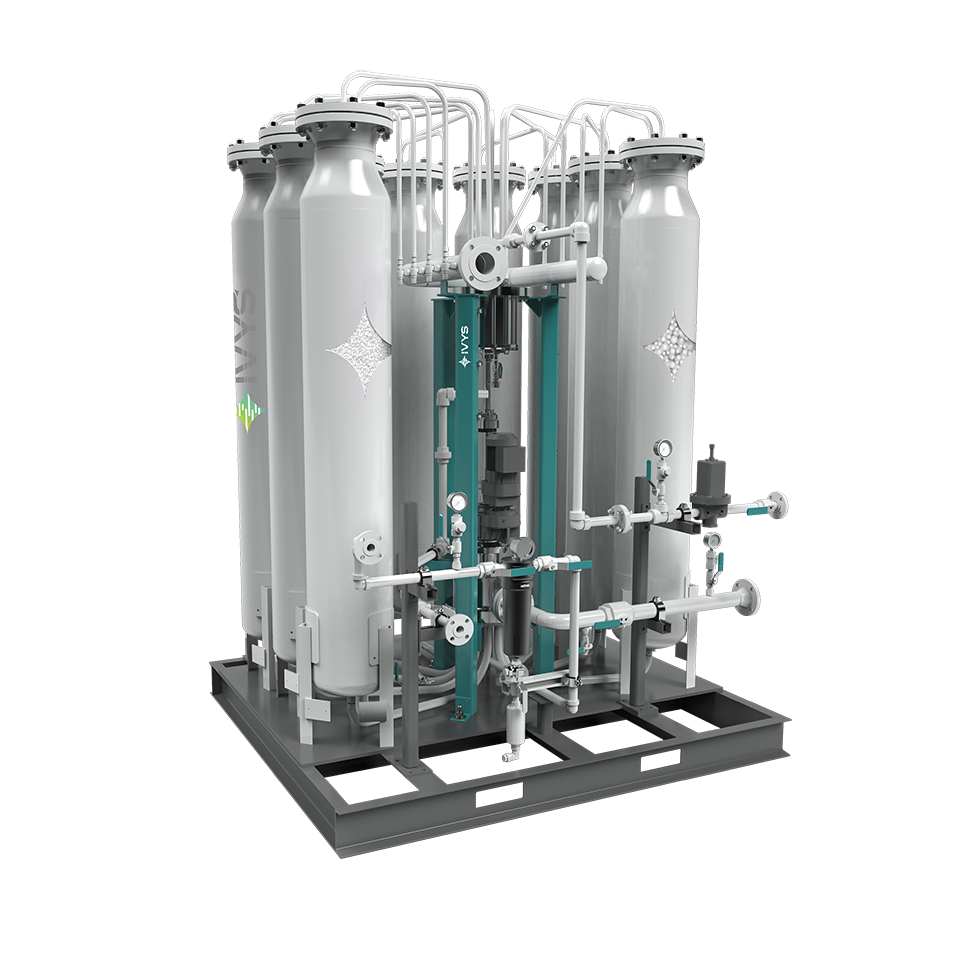

- Innovative rotary-valve, multi-bed pressure swing adsorption (PSA) technology that ensures reliable hydrogen purification to SAE mobility specifications.

- Ivys’ PSA delivers up to 99.9999% purity, exceeding standards requirements.

- They have availability greater than 99.5%.

- Their compact size reduces the footprint often required by other PSA or membrane technology.

- Low operating cost with 0.25 – 1Kw power rating.

- Flexible capacity with 100-40% turndown range

- Skid-mounted for plug-and-play

Easy-to-use control systems that provide high performance and reliability while requiring no specialized training.

Learn how Ivys’ PSA systems for ultra-high purity hydrogen work

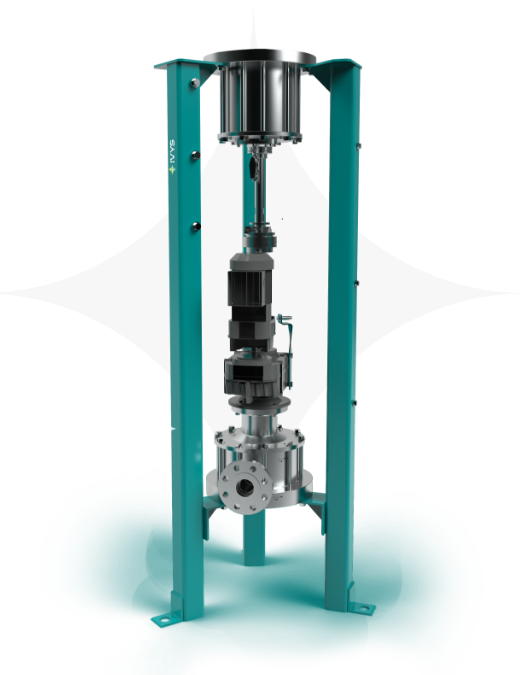

Hydrogen Refueling

- Best-in-class high-purity hydrogen compression and dispensing technologies,

- Proven and innovative low-cost H35 and H70 vehicular dispensing with flexibility to dispense across medium-duty buses/trucks and light-duty passenger vehicles

Learn about Ivys’ H35 and H70 Hydrogen Dispensing Products

Systems Integration and Installation

- Modular and scalable product architecture that enables optimized solutions for customer needs,

- Easy-to-use control systems that provide high performance and reliability while requiring no specialized training.

Results

All those involved are optimistic that this family of products will become the gold standard for H2 generation projects at the megawatt scale and beyond.

When complete, the (SOEC) Hydrogen Post-Processing and Coach Fueling Demonstration project could serve as a working example of economically viable hydrogen processing, purification, and fueling solutions for other fleet and facility managers and ultimately aid in decarbonizing transportation.

This project is still in the detailed design phase. As the project continues, we will share its results on our website. It is expected to be operational by mid-year 2025.

The team of providers collaborating for successful hydrogen project delivery

About Idaho National Laboratory

Battelle Energy Alliance manages INL for the U.S. Department of Energy’s Office of Nuclear Energy. INL is the nation’s center for nuclear energy research and development, celebrating 75 years of scientific innovations in 2024. The laboratory performs research in each of DOE’s strategic goal areas: energy, national security, science and the environment. For more information, visit www.inl.gov. Follow us on social media: Facebook, Instagram, LinkedIn and X.

About Ivys Energy Solutions

Ivys Energy Solutions is a leading provider of smart infrastructure solutions for fleet electrification. We bring together decades of expertise in developing and deploying hydrogen refueling systems and EV charging products with V2G capability that help enable the adoption of zero-emission vehicles. Our 35 and 70 MPa hydrogen dispensers and SimpleFuel stations are widely recognized for their reliability and flexibility, all designed to meet or exceed industry standards and proudly manufactured in the USA.

Visit their website here. ivysinc.com

About Ivys Adsorption

Ivys Adsorption Inc., a Canadian company founded in 2023 by Ivys Energy Solutions, Enbridge, and a group of private owners, acquired Xebec Adsorption assets, including the patented pressure swing adsorption (PSA) technology. Ivys Adsorption designs, manufactures, and services customers in renewable natural gas, hydrogen, carbon capture, helium, and compressed air markets globally.