An Overview of Industrial Air Compressors: Types, Benefits, and Applications

Air compressors are crucial in various industries. They deliver a dependable compressed air source, serving as the backbone for many applications. This article will discuss the four main types of industrial air compressors: oil-lubricated screw compressors, oil-free compressors, reciprocating compressors, and portable compressors. Each type has unique features and benefits that make it suitable for specific applications. Understanding the differences between these air compressors can help businesses select the best system for their needs.

Oil-Lubricated Screw Compressors

Oil-lubricated screw compressors, also known as oil-injected compressors, use oil in the compression chamber to lubricate, seal, and cool the screws in the air end. This type of compressor is generally more robust and durable, making it a popular choice in industries that require long-running equipment.

Benefits

- Durability and Longevity: The oil acts as a lubricant and coolant, reducing wear on internal components, which can result in a longer lifespan for the compressor. It also reduces friction, helping the machine to perform efficiently under heavy workloads.

- High Power and Efficiency: Oil-lubricated screw compressors can generate higher pressures and are more energy-efficient than oil-free models. This makes them ideal for applications requiring constant, high-powered compressed air output.

- Cooling Capabilities: Oil helps dissipate the heat generated during compression, reducing the risk of overheating.

Suitable Industries

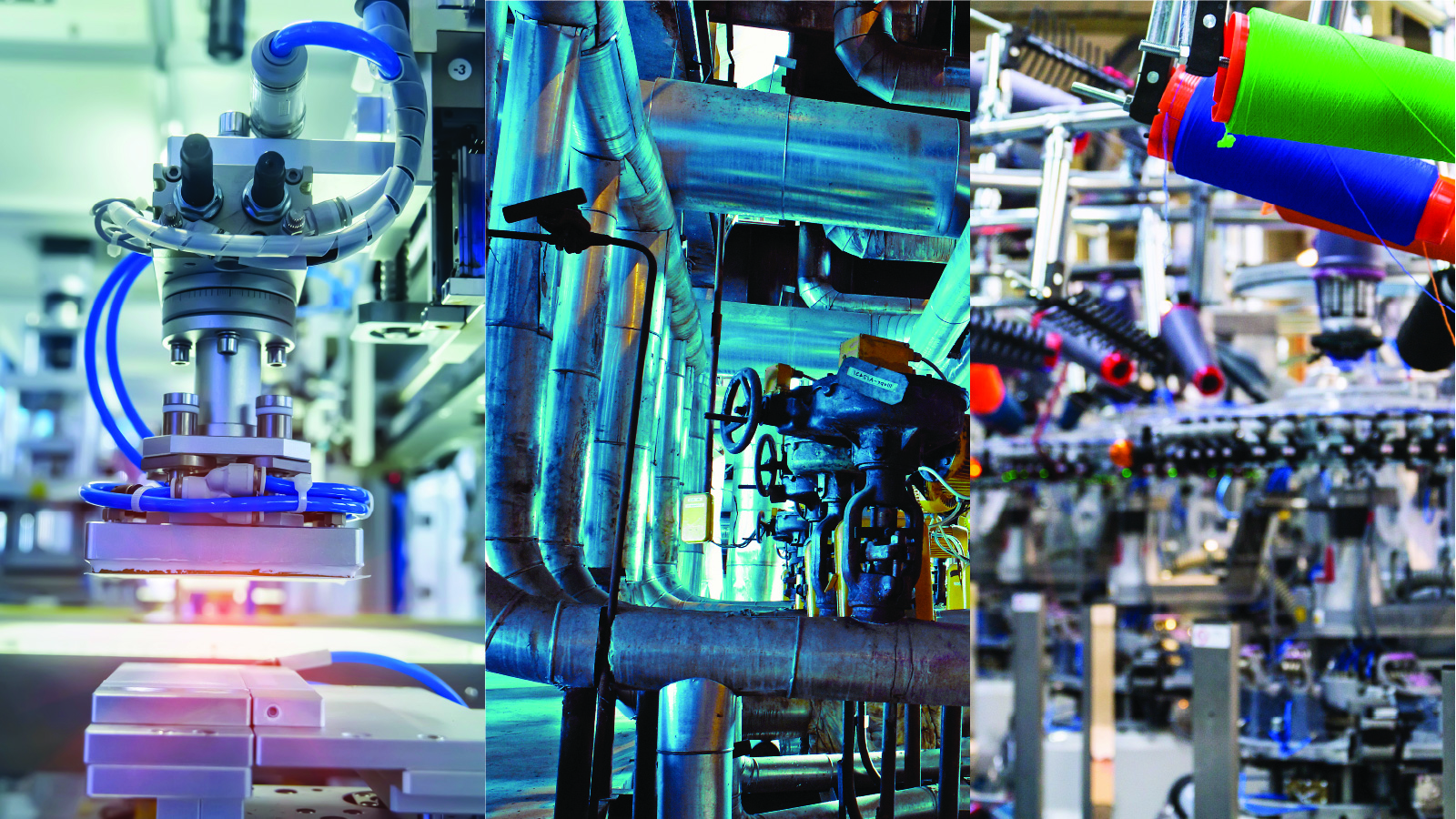

- Manufacturing and Metalwork: Oil-lubricated screw compressors are widely used in manufacturing, metal fabrication, and automotive industries, where continuous high-pressure air is needed for operating pneumatic tools, spray painting, and sandblasting.

- Textiles: In the textile industry, these compressors assist in the operation of machinery used for spinning, weaving, and dyeing.

- Energy Sector: In the energy sector, oil-flooded screw compressors are used for gas compression, in power plants, and for various applications in oil and gas extraction.

Considerations

While oil-lubricated compressors are powerful and durable, they do require regular maintenance, including oil changes and filtration system upkeep to prevent contamination of the compressed air..

Oil-Free Compressors

As the name suggests, oil-free compressors do not use oil in the compression process. Instead, they rely on other means, such as air aftercoolers or water-based cooling systems, to reduce the compression-related temperatures inside the compressor.

Benefits

- Clean Air Output: Since there is no oil involved in the compression process, oil-free compressors produce 100% contaminant-free air. This makes them suitable for applications where pure, clean air is essential.

- Lower Maintenance: Oil-free compressors do not require air/oil separator element changes, which means lower maintenance costs and less downtime. This simplicity often translates into longer intervals between servicing.

- Environmental and Safety Advantages: Oil-free compressors are environmentally friendly, eliminating the risk of oil contamination in sensitive environments.

Suitable Industries

- Food and Beverage: Oil-free compressors are essential in food and beverage processing, packaging, and bottling, where air quality and cleanliness standards are stringent.

- Pharmaceuticals and Medical Fields: Medical devices and pharmaceutical production often rely on oil-free air compressors for hygienic packaging, manufacturing, and operating precision tools, ensuring no contamination occurs.

- Electronics: In the electronics industry, oil-free compressors are critical for applications where even trace amounts of oil can damage sensitive components.

Considerations

Oil-free compressors, while cleaner and requiring less maintenance, typically have a shorter lifespan compared to oil-lubricated models. They may also generate less pressure and are less efficient for heavy-duty industrial applications.

Reciprocating Compressors

Reciprocating compressors, also known as piston compressors, are one of the most commonly used types of compressors. They operate by compressing air through a piston inside a cylinder that moves up and down. Depending on the specific model, these compressors can be oil-lubricated or oil-free.

Benefits

- High Power and Pressure: Reciprocating compressors are capable of generating high pressure, making them suitable for applications requiring powerful air output.

- Variety of Configurations: Reciprocating compressors are available in multiple-stage configurations, depending on the required utilization pressure. Most are single-stage (for lower pressures) and two-stage (for higher pressures) configurations, offering flexibility based on the required air pressure.

- Cost-Effective: These compressors tend to be more affordable than other high-power compressors, making them a cost-effective solution for businesses that need reliable air power without a massive initial investment.

Suitable Industries

- Automotive Repair: Reciprocating compressors are commonly used in auto repair shops to power tools such as air wrenches, spray guns, and tire inflators.

- Small Manufacturing and Workshops: They are ideal for small-scale manufacturing, woodworking, and other workshops where intermittent use of compressed air is required.

- Agriculture: Reciprocating compressors are used in agricultural applications, including powering pneumatic equipment for irrigation systems and handling grain.

Considerations

While reciprocating compressors are powerful and cost-effective, they are not designed for continuous use. They may require frequent maintenance due to the wear on moving parts, particularly in high-demand environments.

Portable Compressors

Portable compressors are compact and designed for easy transportation. These compressors come in various types, including reciprocating and rotary screw models, offering flexibility for mobile work applications. Portable compressors can be oil-lubricated or oil-free, depending on the requirements of the specific task, and depending on capacity, they may run on gas or diesel fuel.

Benefits

- Mobility and Versatility: Portable compressors’ main advantage is their ease of mobility, making them ideal for jobs that require moving from site to site or reaching remote areas. They can be mounted on trailers or designed with wheels for easy transportation.

- Compact Size: Despite their small size, portable compressors can deliver a powerful air supply, especially in models with higher horsepower. This makes them useful for temporary or mobile applications where space is limited.

- Quick Setup: Portable compressors are designed for ease of use, offering a quick setup and minimal installation, making them ideal for temporary or short-term projects.

Suitable Industries

- Construction and Roadwork: Portable compressors are a go-to option for construction sites, roadwork, and repairs. They power pneumatic tools such as drills, hammers, and nail guns.

- Emergency Services and Repairs: They are commonly used in emergency repair operations and disaster relief efforts to provide compressed air in areas with limited power and resources.

- Home Renovations and DIY Projects: Portable compressors are frequently used for DIY home improvement projects where air tools are necessary, but a permanent compressor installation is not feasible.

Considerations

Although portable compressors offer convenience and mobility, they may not deliver the same power and air output as stationary models. Therefore, they are typically best suited for lighter, temporary task.

Selecting the correct type of air compressor depends on the application’s specific needs. Oil-lubricated compressors are ideal for heavy-duty industrial use where durability and power are crucial. In contrast, oil-free compressors provide clean, maintenance-free air for sensitive industries such as food processing and pharmaceuticals. Reciprocating compressors offer a cost-effective solution for smaller shops and intermittent use, while portable compressors deliver versatility and mobility for on-the-go tasks. By understanding the benefits and applications of each type, you can make an informed decision to enhance productivity and efficiency.

Discover the full range of top-quality compressors, including a variety of models from Elgi, at Ivys. Our team of air compression experts is ready to guide you in selecting the perfect compressor model to meet your specific needs.