Nothing Comes Out Clean Without Filtration

Effective filtration is essential in compressed air systems, as it removes contaminants that can compromise both performance and efficiency. The only point in the pneumatic system where creating differential pressure is beneficial is at the filter. To effectively remove contaminants, we need forces—such as centrifugal force or differential pressure—to separate oil and particles from the fluid. This is why filters and the associated differential pressure are crucial in pneumatic systems.

Here are key points to consider:

- Energy Efficiency: As a general rule of thumb, every 2 psi reduction in compressor discharge pressure leads to a 1% decrease in energy consumption. Therefore, choosing filters that maintain low initial differential pressure while delivering excellent performance is vital.

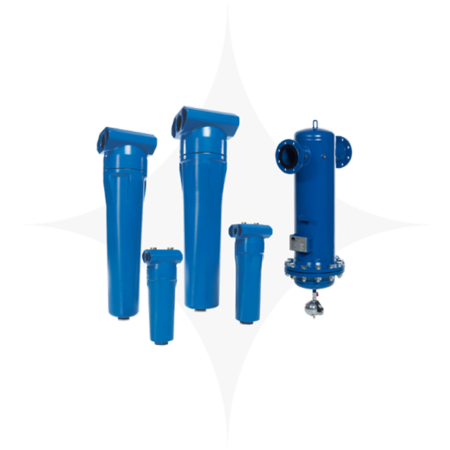

- KSI’s Innovative Filters: Ivys proudly introduces KSI’s new series of filters, which provide the lowest initial differential pressure on the market without sacrificing efficiency. All KSI filters are certified to ISO 12500 standards, ensuring maximum reliability.

KSI’s testing center

- Advanced Technology: KSI’s advanced technologies, including high-density deep-bed pleating and a filtration surface 250% larger than conventional pleated elements, can help users achieve significant energy savings. These filters reduce wet differential pressure by 1.6 psig (about 55% lower than other brands), leading to substantial improvements in energy efficiency. For instance, if a 250 kW (approximately 300 HP) compressor achieves a 55% reduction in discharge pressure, potential energy savings can amount to thousands of dollars.

High-density deep-bed pleating

- Quality and Availability: These high-quality filters are manufactured in Germany and readily available in Ontario and Quebec, allowing customers to save even more on costs. KSI filters meet three essential criteria for customer satisfaction—cost savings, availability, and high quality.

In summary, investing in efficient filtration ensures cleaner compressed air and enhances the overall energy efficiency of compressed air systems. By selecting KSI filters, users can lower differential pressure, resulting in energy savings and improved performance.