The Hidden Cost of Compressors: Why Lifecycle Cost Matters More Than Purchase Price

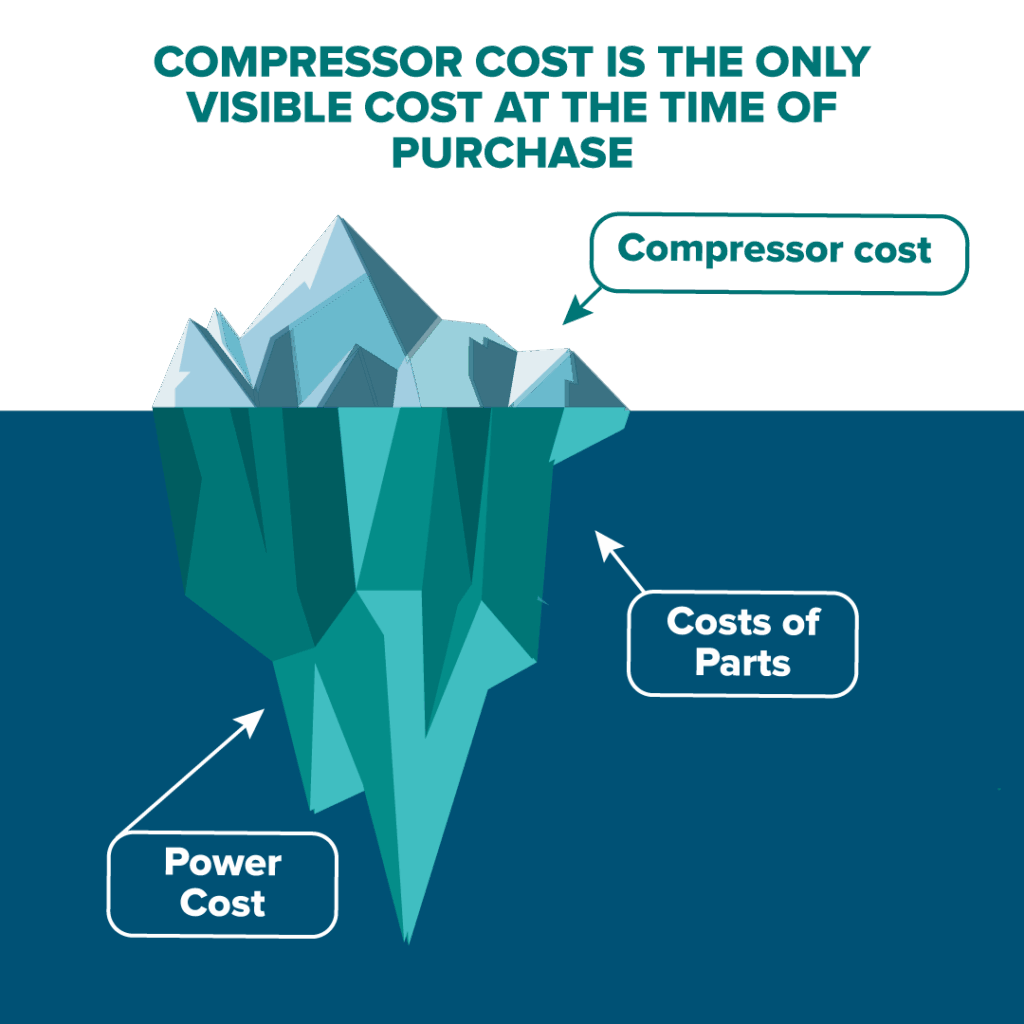

When it comes to investing in an industrial air compressor, many companies focus only on the purchase price. But what you see upfront

is just the tip of the iceberg. In reality, the total cost of ownership — also known as the lifecycle cost (LCC) — represents the true

investment, and it can be significantly higher than expected.

At Ivys Adsorption, we believe that understanding these hidden costs is the key to making smarter, more profitable decisions.

The Iceberg Effect: What You Don’t See Will Cost You

The purchase price of a compressor is only the tip of the iceberg. In reality, it represents just a small fraction of the total expenses tied to its operation over its entire lifetime. Beneath the surface lie much larger costs—costs that many businesses continue to underestimate.

Behind every compressor, several critical factors must be considered, including:

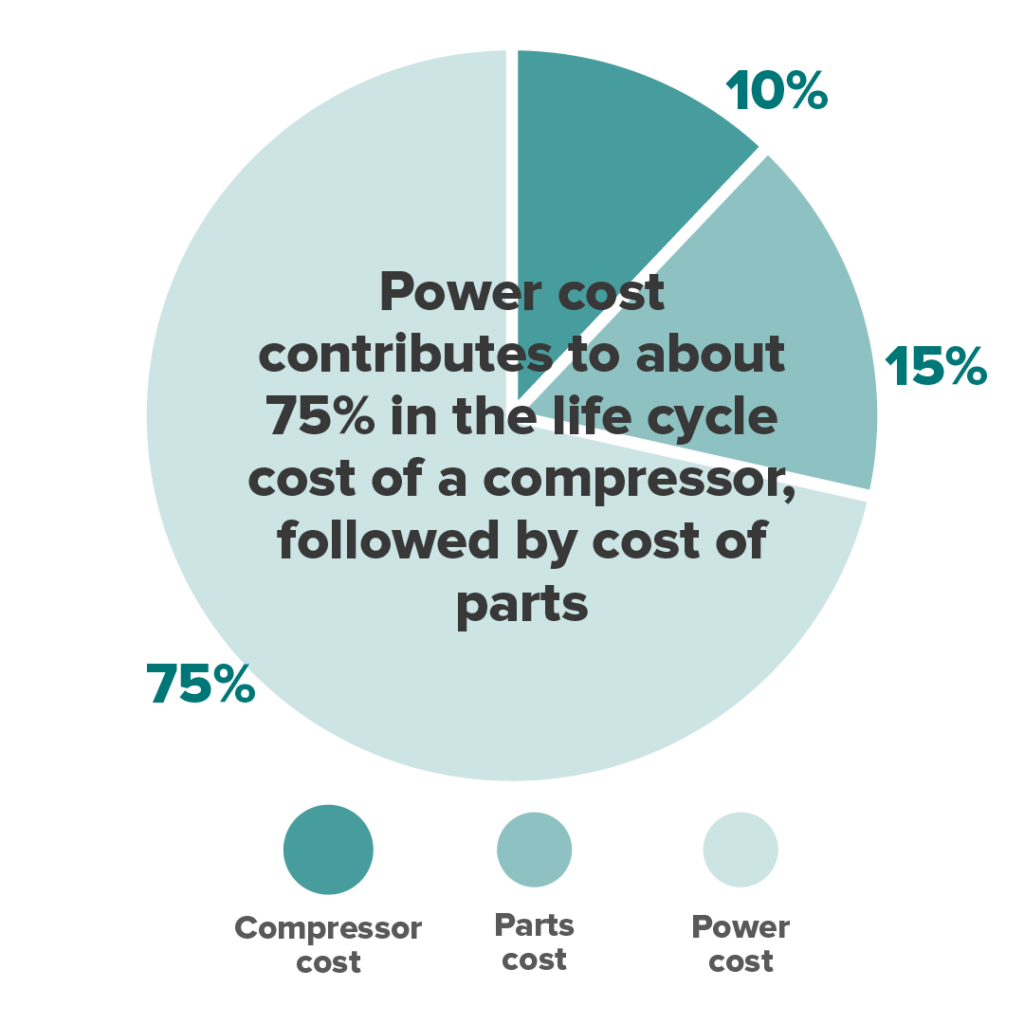

- Energy consumption, which alone can account for up to 70% of the Life Cycle Cost (LCC). An improperly sized or poorly maintained system can cause this expense to skyrocket.

- Maintenance and spare parts, essential to ensure reliability and extend the equipment’s lifespan. Cutting corners in the short term often leads to higher expenses down the road.

- Production downtime and lost productivity, which occur when unexpected failures strike. Every minute of downtime translates into lost revenue, reduced performance, and additional strain on your teams.

These “hidden costs” accumulate silently and can weigh heavily on your financial results. More often than not, it isn’t the visible expenses that jeopardize profitability, but the ones lurking below the surface, just like the submerged part of an iceberg.

The key lies in proactive and strategic planning: selecting a reliable partner, investing in energy-efficient solutions, conducting regular maintenance, and anticipating parts requirements. By taking this approach, companies can transform what would otherwise be a source of loss into a powerful driver of efficiency and long-term profitability.

Three Ways to Reduce Lifecycle Costs

- Energy Efficiency

Modern solutions like ELGi’s EG Series with Variable Frequency Drive (VFD) can cut energy usage by up to 35%, delivering long-term savings that far outweigh the initial investment. - Predictive Maintenance

Smart monitoring systems such as Air~Alert help detect potential issues before they cause breakdowns. This proactive approach prevents costly downtime and reduces repair expenses. - Reliability and Local Support

Beyond the technology, choosing the right partner is crucial. With ELGi’s industry-leading warranties (5 years package, lifetime coverage on the airend for EG Series, and 6 years on EN Series) and Ivys Adsorption’s local service and spare parts availability, you’re guaranteed peace of mind and uninterrupted operations.

Why Choose Ivys Adsorption?

As the official distributor of ELGi compressors in Quebec and Ontario, Ivys Adsorption combines global innovation with local expertise. We don’t just sell compressors—we partner with you to ensure your investment delivers maximum value throughout its lifecycle.

Our team provides:

- Tailored recommendations based on your operational needs

- Fast and reliable technical support

- Access to genuine spare parts and long-term service solutions

The Bottom Line

Don’t let hidden costs sink your profits. By focusing on lifecycle cost instead of the sticker price, you’ll make a smarter, more sustainable investment in your operations.

With Ivys Adsorption and ELGi compressors, you can be confident that what you don’t see won’t cost you more.

Contact our team today to learn how we can optimize your compressed air systems for long-term efficiency and savings.