PSA

Carbone capture

Conditioning

Carbon Dioxide Removal from Air

Ivys' HRS-SGX adsorption purifier is designed to remove carbon dioxide from air. From an air flow of 12,000 scfm, our adsorption purifier reduces CO2 from levels of 400 ppm down to 20 ppm, all on a footprint that is two-thirds smaller than conventional adsorber designs for similar applications.

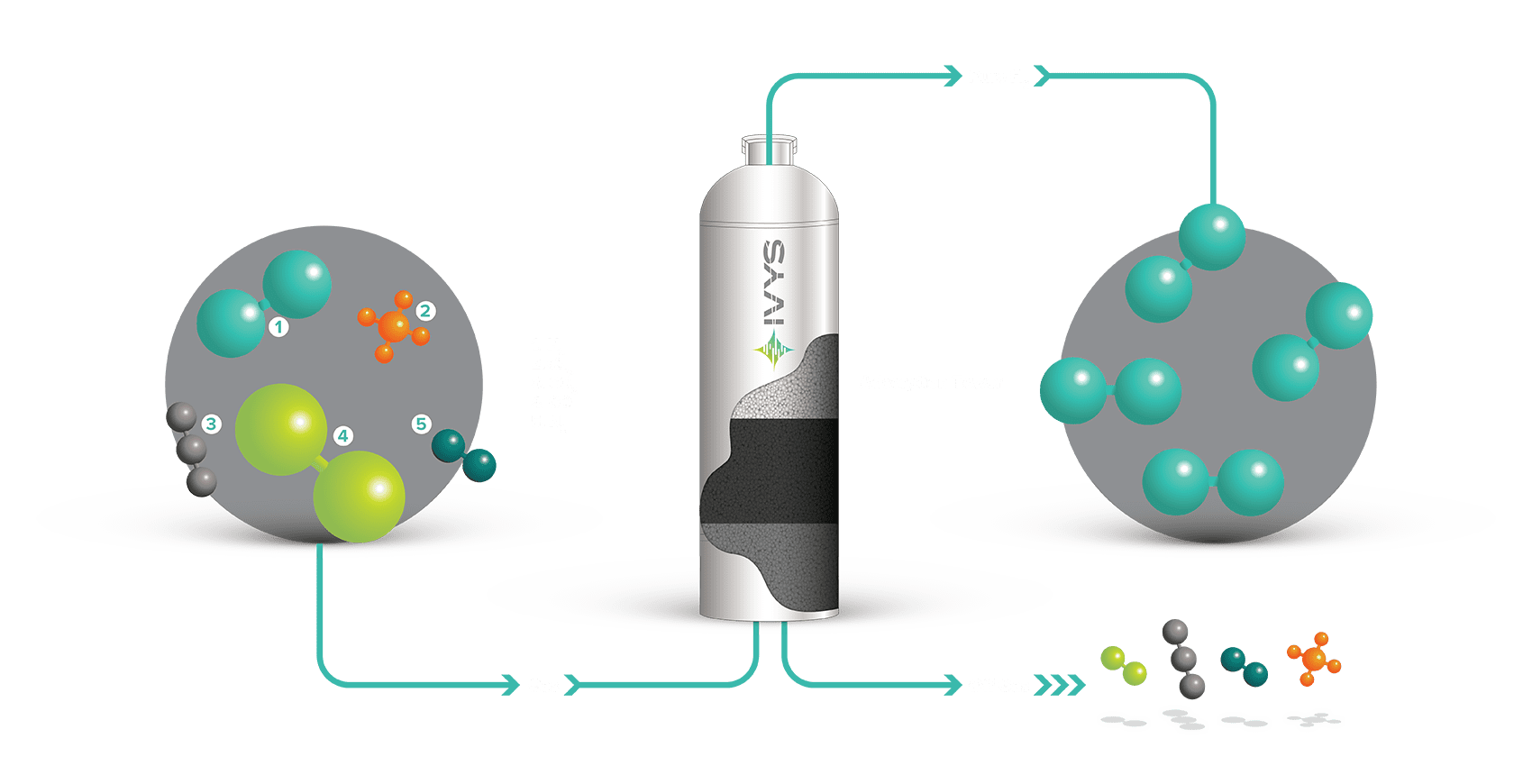

Hydrogen purification

Understanding

Ivys technology

Specifications

| Feed Process Gas (vol%) | G0 | G1 | G2 | G3 | G4 |

|---|---|---|---|---|---|

| Number of Beds | 6 | 8 | 9 | 9 | 9 |

| Bed Diameter | 14”-48” | 3” | 2”-12” | 14”20” | 20”-42” |

| Maximum Operating Pressure | 450 psig | 175 psig | 300 psig | 250 psig | 250 psig |

| Feed Capacity (NCMH) | 1,200-15,500 | 10-45 | 25-950 | 1,450-3,100 | 4,500-29,000 |

| Feed Gas Temp (°C) | 10-60 with 20-45 preferred | ||||

| Design Standards | North America: ASME, NFPA, NEC, CSA / Europe: PED, ATEX, IEC | ||||

| Voltage | 120Vac/1ph/60Hz, 240Vac/3ph/50 or 60Hz, 380Vac/3ph/50Hz, 480Vac/3ph/60Hz | ||||

| Power Consumption | 0.2-0.5 kw typical | ||||

| Design Life | 15+ years with scheduled maintenance, 10+years for adsorbents | ||||

| Recommended Service | Inspection every 2.5 years; Minimum seal life 5 years | ||||

Typical Hydrogen Source Gas

| Feed Process Gas (vol%) | H2 | CO | CO2 | CH4 | CH2-3 | CH4 + | N2 | H2O Vapor |

|---|---|---|---|---|---|---|---|---|

| MSR SYNGAS | 60-80 | 0-10 | 10-20 | 0-10 | Sat. | |||

| ATR SYNGAS | 40-60 | 0-10 | 15-25 | 0-10 | 0-30 | Sat. | ||

| CPOX SYNGAS | 30-50 | 0-10 | 15-25 | 0-10 | 0-20 | Sat. | ||

| GASIFICATION GAS | 20-60 | 0-20 | 0-20 | 0-20 | 0-10 | 0-5 | 0-10 | Sat. |

| REFINERY OFF-GAS | 30-90 | 0-30 | 0-30 | 0-30 | 0-30 | 0-5 | Sat. | |

| H2 POLISHING | 90-99 | Sat. | ||||||

| AMMONIA CRACKING | 60-75 | 25-50 |

Performance

| H2 PURITY | Up to 99.9999 % |

| RECOVERY | 80-90 % typical. Recovery depends strongly on feed gas composition,pressure and product purity requirements. |

| TURNDOWN | 40-100 % |

| AVAILABILITY | Up to 99.9999 % |

| APPLICATIONS |

|

Specifications

| H-series Frame Size |

Vessel Outside Diameter |

Rotary Valve / # of Beds |

Max Op.Pressure | Feed Flow Capacity1 | Dimensions3 | Weight2 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Width | Depth | Height | ||||||||||||

| PSIG | BARG | SNFM | Nm3/hr | ft | m | ft | m | ft | m | lbs | kgs | |||

| H-3100 | 14" | G0-6BED | 450 | 31 | 750 | 1,200 | 10.5 | 3.2 | 9.0 | 2.7 | 12.0 | 3.6 | 15,000 | 6,800 |

| 16" | 1,000 | 1,600 | 10.7 | 3.3 | 9.3 | 2.8 | 12.0 | 3.6 | 16,000 | 7,300 | ||||

| 18" | 1,250 | 2,000 | 10.9 | 3.3 | 9.3 | 2.8 | 12.0 | 3.6 | 17,000 | 7,700 | ||||

| 20" | 1,600 | 2,550 | 11.1 | 3.4 | 9.5 | 2.9 | 12.0 | 3.6 | 19,000 | 8,600 | ||||

| 24" | 2,300 | 3,700 | 11.6 | 3.5 | 10.0 | 3.0 | 12.0 | 3.6 | 21,000 | 9,500 | ||||

| 30" | 3,900 | 6,000 | 12.6 | 3.8 | 11.0 | 3.3 | 12.0 | 3.6 | 24,000 | 11,000 | ||||

| 36" | 5,350 | 8,500 | 13.6 | 4.1 | 12.0 | 3.6 | 16.2 | 4.9 | 28,000 | 17,000 | ||||

| 42" | 7,400 | 11,700 | 14.6 | 4.4 | 13.0 | 4.0 | 16.2 | 4.9 | 32,000 | 14,500 | ||||

| 48" | 9,800 | 15,500 | 15.6 | 4.7 | 14.0 | 4.3 | 16.2 | 4.9 | 36,000 | 16,300 | ||||

| H-3200 | 2" | G2-9BED | 300 | 21 | 15 | 25 | 4.7 | 1.4 | 3.7 | 1.1 | 7.6 | 2.3 | 3,850 | 1,750 |

| 4" | 65 | 100 | 4.7 | 1.4 | 3.7 | 1.1 | 7.6 | 2.3 | 3,900 | 1,800 | ||||

| 6" | 145 | 230 | 4.7 | 1.4 | 3.7 | 1.1 | 7.6 | 2.3 | 4,550 | 2,050 | ||||

| 8" | 275 | 430 | 5.3 | 1.6 | 5.3 | 1.6 | 9.5 | 2.9 | 4,900 | 2,200 | ||||

| 10" | 420 | 670 | 5.5 | 1.7 | 5.3 | 1.6 | 9.5 | 2.9 | 5,100 | 2,300 | ||||

| 12" | 600 | 950 | 6.3 | 1.9 | 5.8 | 1.8 | 9.5 | 2.9 | 5,400 | 2,450 | ||||

| H-3200 | 14" | G3-9BED | 250 | 17 | 900 | 1,450 | 18.4 | 5.6 | 8.4 | 2.6 | 13.6 | 4.1 | 18,500 | 8,400 |

| 16" | 1,200 | 1,950 | 18.6 | 5.6 | 8.5 | 2.6 | 13.6 | 4.1 | 20,000 | 9,100 | ||||

| 18" | 1,600 | 2,550 | 18.8 | 5.7 | 8.8 | 2.7 | 13.6 | 4.1 | 21,500 | 9,800 | ||||

| 20" | 1,950 | 3,100 | 19.0 | 5.8 | 9.0 | 2.7 | 13.6 | 4.1 | 23,000 | 10,500 | ||||

| H-3200 | 24" | G4-9 BED | 250 | 17 | 2,800 | 4,500 | 21.0 | 6.4 | 10.5 | 3.2 | 14.0 | 4.3 | 28,000 | 12,700 |

| 30” | 4,500 | 7,100 | 23.5 | 7.2 | 12.0 | 3.6 | 14.0 | 4.3 | 32,500 | 14,750 | ||||

| 36” | 6,650 | 10,500 | 27.0 | 8.2 | 13.5 | 4.1 | 18.3 | 5.6 | 37,000 | 16,800 | ||||

| 42” | 8,850 | 14,000 | 30.0 | 9.1 | 15.0 | 4.6 | 18.3 | 5.6 | 41,500 | 18,850 | ||||

| 48” | 11,700 | 18,500 | 33.0 | 10.1 | 16.5 | 5.0 | 18.3 | 5.6 | 46,000 | 20,900 | ||||

| 54” | 14,900 | 23,500 | 37.0 | 11.3 | 18.0 | 5.5 | 18.3 | 5.6 | 52,000 | 23,600 | ||||

| 60” | 18,350 | 29,000 | 42.0 | 12.8 | 19.5 | 5.9 | 18.3 | 5.6 | 57,000 | 25,900 | ||||

| H-3300 | 3" | G1-9 BED | 175 | 12 | 28 | 45 | 2.6 | 0.9 | 2.8 | 0.9 | 7.3 | 2.2 | 1,500 | 700 |

1Specifications listed above are typical values. Each PSA will be sized individually to customer process requirements.

2Weight = empty

3Dimensions don’t include surge tanks which are sized based on customer process data