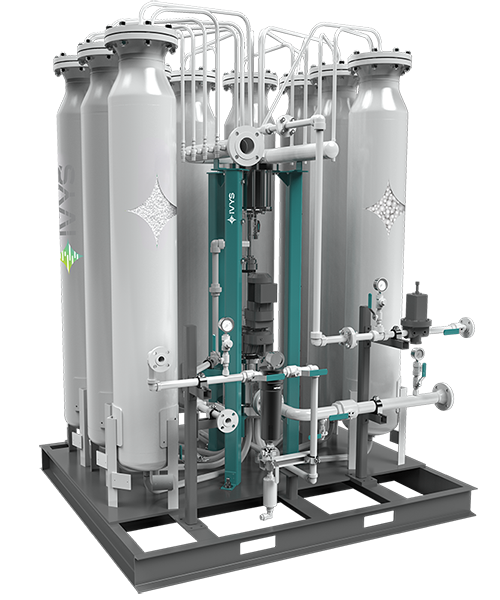

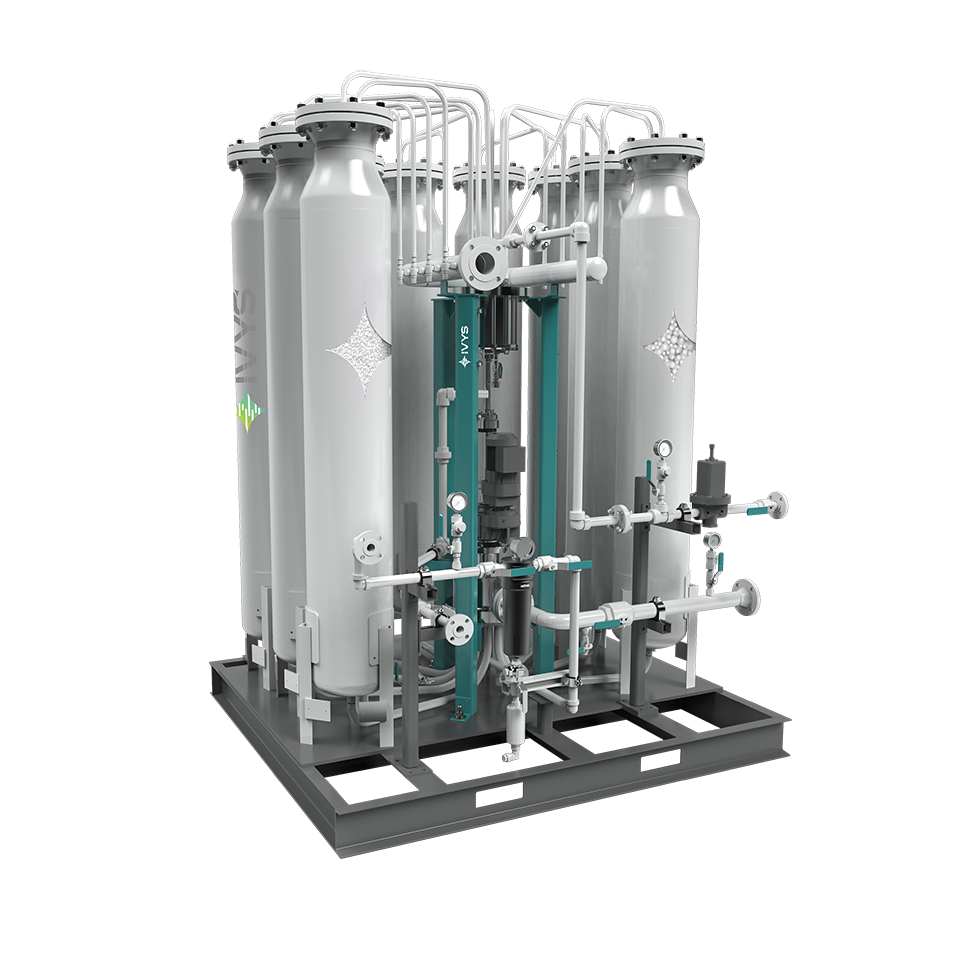

H3200 Series – Fast-Cycle PSA for Ultra-Pure Hydrogen Purification

Ivys

Ivys’ Hydrogen Purification Solutions efficiently purify hydrogen-containing reformate, petrochemical process gas streams and refinery off-gas streams to pure and ultra-pure hydrogen. Ivys provides the most compact, economical and reliable PSA systems available today.

Hydrogen purification

Understanding

Ivys technology

Specifications

System Configurations

| H3200 G2 |

H3200 G3 |

H3200 G4 |

|||

|---|---|---|---|---|---|

| Number of Beds | 9 | 9 | 9 | ||

| Bed Diameter | 2”-12” | 14”20” | 20”-42” | ||

| Maximum Operating Pressure | 300 psig | 250 psig | 250 psig | ||

| Feed Capacity (NCMH) | 25-950 | 1,450-3,100 | 4,500-29,000 | ||

| Feed Gas Temp (°C) | 10-60 with 20-45 preferred | ||||

| Design Standards | North America: ASME, NFPA, NEC, CSA / Europe: PED, ATEX, IEC | ||||

| Voltage | 120Vac/1ph/60Hz, 240Vac/3ph/50 or 60Hz, 380Vac/3ph/50Hz, 480Vac/3ph/60Hz | ||||

| Power Consumption | 0.2-0.5 kw typical | ||||

| Design Life | 15+ years with scheduled maintenance, 10+years for adsorbents | ||||

| Recommended Service | Inspection every 2.5 years; Minimum seal life 5 years | ||||

Typical Hydrogen Source Gas

| Feed Process Gas (vol%) | H2 | CO | CO2 | CH4 | CH2-3 | CH4 + | N2 | H2O Vapor |

|---|---|---|---|---|---|---|---|---|

| MSR SYNGAS | 60-80 | 0-10 | 10-20 | 0-10 | Sat. | |||

| ATR SYNGAS | 40-60 | 0-10 | 15-25 | 0-10 | 0-30 | Sat. | ||

| CPOX SYNGAS | 30-50 | 0-10 | 15-25 | 0-10 | 0-20 | Sat. | ||

| GASIFICATION GAS | 20-60 | 0-20 | 0-20 | 0-20 | 0-10 | 0-5 | 0-10 | Sat. |

| REFINERY OFF-GAS | 30-90 | 0-30 | 0-30 | 0-30 | 0-30 | 0-5 | Sat. | |

| H2 POLISHING | 90-99 | Sat. | ||||||

| AMMONIA CRACKING | 60-75 | 25-50 |

Performance

| H2 PURITY | Up to 99.9999 % |

| RECOVERY | 80-90 % typical. Recovery depends strongly on feed gas composition, pressure and product purity requirements. |

| TURNDOWN | 40-100 % |

| AVAILABILITY | Up to 99.9999 % |

| APPLICATIONS |

|

Specifications

| H-series Frame Size |

Vessel Outside Diameter |

Rotary Valve / # of Beds |

Max Op.Pressure | Feed Flow Capacity1 | Dimensions3 | Weight2 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Width | Depth | Height | ||||||||||||

| PSIG | BARG | SNFM | Nm3/hr | ft | m | ft | m | ft | m | lbs | kgs | |||

| H-3200 | 2" | G2-9BED | 300 | 21 | 15 | 25 | 4.7 | 1.4 | 3.7 | 1.1 | 7.6 | 2.3 | 3,850 | 1,750 |

| 4" | 65 | 100 | 4.7 | 1.4 | 3.7 | 1.1 | 7.6 | 2.3 | 3,900 | 1,800 | ||||

| 6" | 145 | 230 | 4.7 | 1.4 | 3.7 | 1.1 | 7.6 | 2.3 | 4,550 | 2,050 | ||||

| 8" | 275 | 430 | 5.3 | 1.6 | 5.3 | 1.6 | 9.5 | 2.9 | 4,900 | 2,200 | ||||

| 10" | 420 | 670 | 5.5 | 1.7 | 5.3 | 1.6 | 9.5 | 2.9 | 5,100 | 2,300 | ||||

| 12" | 600 | 950 | 6.3 | 1.9 | 5.8 | 1.8 | 9.5 | 2.9 | 5,400 | 2,450 | ||||

| H-3200 | 14" | G3-9BED | 250 | 17 | 900 | 1,450 | 18.4 | 5.6 | 8.4 | 2.6 | 13.6 | 4.1 | 18,500 | 8,400 |

| 16" | 1,200 | 1,950 | 18.6 | 5.6 | 8.5 | 2.6 | 13.6 | 4.1 | 20,000 | 9,100 | ||||

| 18" | 1,600 | 2,550 | 18.8 | 5.7 | 8.8 | 2.7 | 13.6 | 4.1 | 21,500 | 9,800 | ||||

| 20" | 1,950 | 3,100 | 19.0 | 5.8 | 9.0 | 2.7 | 13.6 | 4.1 | 23,000 | 10,500 | ||||

| H-3200 | 24" | G4-9 BED | 250 | 17 | 2,800 | 4,500 | 21.0 | 6.4 | 10.5 | 3.2 | 14.0 | 4.3 | 28,000 | 12,700 |

| 30” | 4,500 | 7,100 | 23.5 | 7.2 | 12.0 | 3.6 | 14.0 | 4.3 | 32,500 | 14,750 | ||||

| 36” | 6,650 | 10,500 | 27.0 | 8.2 | 13.5 | 4.1 | 18.3 | 5.6 | 37,000 | 16,800 | ||||

| 42” | 8,850 | 14,000 | 30.0 | 9.1 | 15.0 | 4.6 | 18.3 | 5.6 | 41,500 | 18,850 | ||||

| 48” | 11,700 | 18,500 | 33.0 | 10.1 | 16.5 | 5.0 | 18.3 | 5.6 | 46,000 | 20,900 | ||||

| 54” | 14,900 | 23,500 | 37.0 | 11.3 | 18.0 | 5.5 | 18.3 | 5.6 | 52,000 | 23,600 | ||||

| 60” | 18,350 | 29,000 | 42.0 | 12.8 | 19.5 | 5.9 | 18.3 | 5.6 | 57,000 | 25,900 | ||||

1Specifications listed above are typical values. Each PSA will be sized individually to customer process requirements.

2Weight = empty

3Dimensions don’t include surge tanks which are sized based on customer process data