Make Compressor Maintenance Part of your Spring Cleaning

Spring has finally arrived, signaling the time for spring cleaning. A crucial aspect of this routine is compressor maintenance. Consistent upkeep of your compressor boosts energy efficiency, averts expensive repairs, reduces unexpected downtime, and keeps your compressor operating at its best.

We’ve created this 8-step guide to help you maintain your compressor’s peak performance during the warmer seasons.

1. Refer to your owner’s manual

Each compressor includes manufacturer guidelines and instructions for its maintenance. Ensure that the maintenance checklist is readily accessible and being followed.

2. Daily Visual Checks

Each day, perform a quick visual inspection for oil leaks or loose components. Check the oil level, the MOS condensate, and the condensate in the AOS (air/oil separator) tank. When the compressor oil is too low, it can cause the compressor to overheat and shut down unexpectedly.

3. Check air entry points

Ensure that all air entry points are clear. A clogged input will affect the output of compressed air and may cause the compressor to overheat.

4. Sample your oil

If you haven’t done an oil sampling test in the last 6 months or 2,000 hours, now is the time. Oil sampling tests ensure the oil’s properties are adequate for the coming warmer temperatures.

5. Pre-filters and intake filter inspection and replacement

Pollen, dirt, dust, and insects can damage your compressor’s cooler, especially if it is located outdoors. It is advisable to use pre-filters to eliminate these contaminants.

Pre-filters (for air intake, cooler, and control panel) should be replaced annually or every 4,0000 hours.

6. Check drying equipment

As spring progresses, rising air temperatures and humidity lead to more condensation. This can cause water to accumulate in compressed air lines, damaging tools or production down the production line.

7. Ventilation

Your compressor room must be well-ventilated to keep your compressor cool as temperatures rise. You may want to test any fans and louvers to ensure optimal performance. A well-ventilated compressor operates more efficiently.

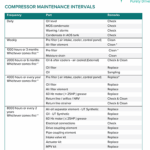

8. Regular maintenance

Ensure your air compressor is always at its best by performing regular preventative maintenance! Sticking to a consistent service schedule is essential for optimal performance and longevity. Don’t overlook this key aspect—keep your compressor running smoothly and efficiently!

We are committed to providing you with top-quality service on your air compressors, dryers and other equipment. We service the most popular compressor brand.

Visit our service page to learn more