Air

Compression

Variable Speed Air Compressor

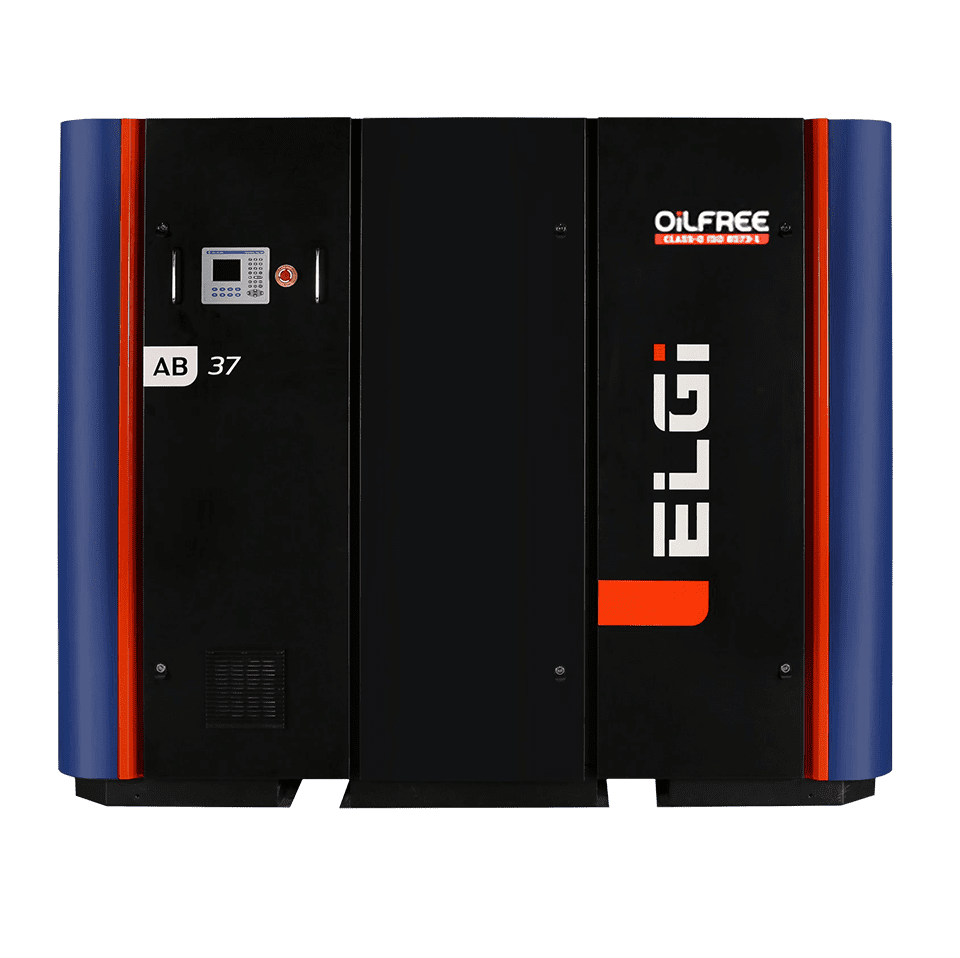

AB SERIES SCREW AIR COMPRESSOR 15 – 150 hp

Elgi

ELGi is one of the very few screw air compressor companies to design and manufacture airends for oil-free screw air compressor technology. The new AB series oil-free screw air compressors provides disruptive benefits in terms of efficiency, reliability and air quality resulting in a lower life cycle cost and high uptime. The high-quality air output with Class-“0” certification makes this compressor ideal for sensitive applications in pharmaceuticals, food and beverage industries where the presence of oil vapor and moisture is intolerable.

Specifications

| Product | Air Quality | Product performance |

|---|---|---|

| CE certified | Class 0 per ISO:8573(p-2):2007 | ISO 1217:2009 |

| Pressurized components | Electricals | Water Quality |

| ASME ‘’U’’ stamping (USA): PED (EU) | UL & CE certified | ISO:10500-2012 |

| Material & Processes | Air Quality for Microbial | Neuron IV Controller |

| FDA approved per EU directive EC 1935/2004 | content ISO:8573-7 |

Advanced communications (CAN, Ethernet) and multiple compressor control |

Attributes and benefits

ENERGY SAVINGS

Highly efficient airend

ELGi’s airends are equipped with in-house developed n-V profile rotors, with a 4/5 lobe combination. The rotors are designed to run at optimum speeds. This unique design reduces pressure losses and increases efficiency. The rotors ensure energy-efficient compressed air supply for all demanding applications.

- Precise rotor clearances for best-in-class energy efficiency.

- Low operating speed for long life, low maintenance, and low sound level.

- Complies with applicable safety standards.

MOISTURE FREE AIR

99% Water Free

Depending on the humidity level of inlet air, bulk water remains in compressed air at varying levels and causes corrosion of piping, end tools, machinery, and valves. AB Series air compressors have a custom-designed centrifugal-type moisture separator with an automatic drain. This comes as a part of the package at no extra cost and removes over 99% of bulk water from the compressed air, resulting in corrosion-free, longer life of end-use equipment and less load on the dryer.

EFFICIENT SEPARATION

Efficient air-water separation with WSBIC (3 stages)

ELGi has applied a unique WSBIC process (Water separation by Impact and Centrifugal Action) which enables efficient separation of air and water with minimum pressure drop. The method enables the separation of water in three stages increasing the life of the separator element.

SAFETY AND PROTECTION

AB series compressors are designed to ensure the highest level of safety for:

- Pressure regulating valve

- High pressure

- High temperature

- Pressure relief valve

- Phase order and single-phase

Applications

Food

Textile

Pharma

Electronics

Automotive

Metals

Oil & Gas

Power