Desiccant air dryer

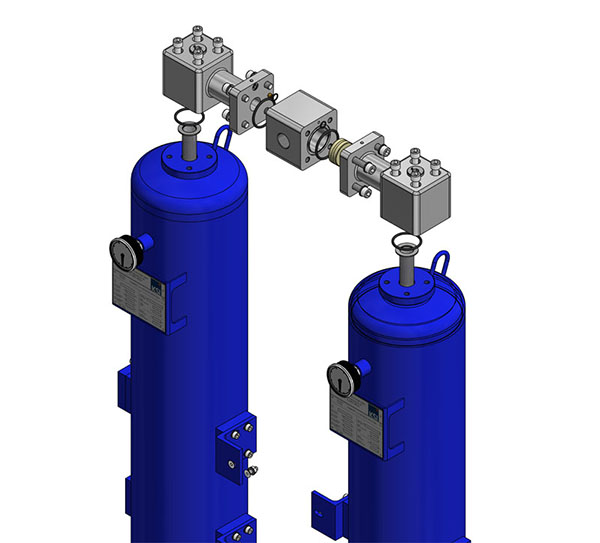

Ecotroc DDN Desiccant Dryers Heatless Regenerated

KSI

Pressure dew point down to -40°F

Capacity up to 705 cfm

Desiccant dryers are used in environments where a specified pressure dew point of -40°F to -94°F must be reliable and safe. Dryers of the ECOTROC DD series are available in three versions: as a compact aluminum series (DDAP) for volume flows up to 110 cfm, with welded vessels (DDN) for volume flows up to 705 cfm as well as in the large version (DDF) up to 1800 cfm*. Higher volume flows are available on request.

Advantages

The ECOTROC DD Plus-Effects

- Change of desiccant via filling and emptying openings

- Disassembly of the complete pipe bridges by loosening just three screws ► Comfortable and fast service work

- Simple and clear service packages

- Easy to understand control unit, simple menu navigation (with ETC 4.0)rn

ATTRIBUTES AND BENEFITS

Specifications

Performance data and dimensions

| Type* | Capacity** | Dimensions (inch) | Connection | Weight | Installed power | Electric voltage | Frequency | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| cfm | A | B | C | D | Intlet | Outlet | lbs | HP | V | Hz | |

| DDN105 | 105 | 53.86 | 35.87 | 31.89 | 23.66 | 1“ | 1“ | 370 | 0.042 | 115 | 50 / 60 |

| DDN125 | 125 | 58.74 | 40.75 | 31.89 | 23.66 | 1“ | 1“ | 406 | 0.042 | 115 | 50 / 60 |

| DDN200 | 200 | 61.81 | 41.26 | 39.96 | 30.55 | 1 1/2“ | 1 1/2“ | 785 | 0.042 | 115 | 50 / 60 |

| DDN285 | 285 | 65.75 | 45.20 | 39.96 | 30.55 | 1 1/2“ | 1 1/2“ | 833 | 0.042 | 115 | 50 / 60 |

| DDN350 | 350 | 83.86 | 63.31 | 39.96 | 30.55 | 1 1/2“ | 1 1/2“ | 1049 | 0.042 | 115 | 50 / 60 |

| DDN480 | 480 | 73.07 | 51.46 | 52.76 | 41.54 | 2“ | 2“ | 1629 | 0.042 | 115 | 50 / 60 |

| DDN590 | 590 | 84.88 | 63.27 | 52.76 | 41.54 | 2“ | 2“ | 1836 | 0.042 | 115 | 50 / 60 |

| DDN705 | 705 | 88.82 | 67.20 | 52.76 | 41.54 | 2“ | 2“ | 1971 | 0.042 | 115 | 50 / 60 |

*calculated at 14.5 psi (abs.) and 68°F at 101.5 psi working pressure

Correction factors

| Correction factors inlet temperature | |||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| °F | <77 | 77 | 86 | 95 | 100.4 | 104 | 113 | 118.4 | 122 | ||||||||||||||||

| F(t) | 1.2 | 1.1 | 1.09 | 1 | 0.84 | 0.78 | 0.72 | 0.65 | 0.58 | ||||||||||||||||

| Correction factors operating pressure | |||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| psi | 58 | 65 | 73 | 80 | 87 | 94 | 102 | 109 | 116 | 123 | 131 | 138 | 145 | 152 | 160 | 167 | 174 | 181 | 189 | 196 | 203 | 210 | 218 | 225 | 232 |

| F(p) | 0.6 | 0.7 | 0.74 | 0.82 | 0.89 | 0.97 | 1 | 1.08 | 1.11 | 1.16 | 1.22 | 1.29 | 1.36 | 1.42 | 1.5 | 1.57 | 1.63 | 1.69 | 1.75 | 1.83 | 1.9 | 1.96 | 2.03 | 2.1 | 2.14 |

Multiply the capacity of the dryer by the correction factor in the table above and you will get the corrected capacity.

Higher inlet temperatures on request.