Lubricated screw air compressor

EG Series Rotary Screw Air Compressors – 15-300 HP

Elgi

The EG series rotary screw air compressors from ELGi are designed and manufactured in compliance with the applicable international standards (CE, ASME, UL, and others). The EG series has every component designed for reliability and ease of maintenance.

Specifications

| Motor Power | Working Pressure | Airflow |

|---|---|---|

| 11 kW to 250 kW | 4.5 barg to 12.5 barg | 2.01 m3/min to 43.18 m3/min |

Attributes and benefits

Highly Efficient Airend

Superior Energy Efficiency

ELGi’s unique airends are equipped with in-house developed η-V profile rotors, with 4/5 lobe combination.

- Low speed

- Highly energy efficient

- Lifetime warranty*

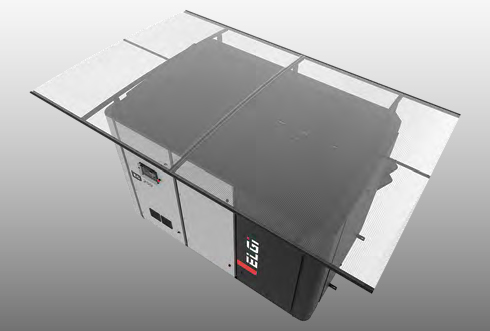

Advanced Package Design

Functional and Aesthetic

The package is configured with subsystems that are designed to:

- Minimize system losses which maximize energy savings

- Ease of service

- Low noise levels

Low Oil Carry Over (less than 1PPM)

Three Stage Oil Removal

Superior Quality of Air

- Minimal pressure drop

- Increases life of air - oil separator filter

- Reduces environmental impact

Efficient Cooling System

Large Cooler and Optimized Fan

- Oversized and bolted cooler design eliminates thermal stresses and extends compressor life

- Lowers power consumption

- Keeps discharged compressed air temperature low easing the load on downstream equipment

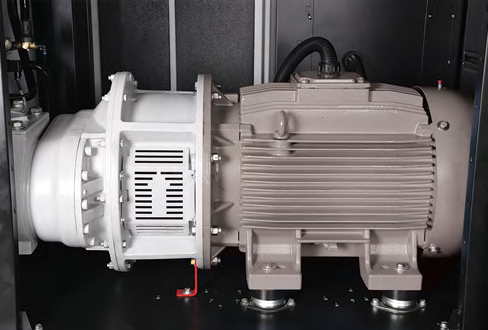

Motors

Reliable and Efficient

The motors with a larger core and increased windings offer:

- TEFC severe duty for industrial applications

- Direct coupling with air end increases energy efficiency

- High ambient rating

Intake Valve System

Integrated Blow-down Unit, Solenoid Control, and Actuator

- Reduces starting load on motor

- Optimal capacity control

- Modulation (55 kW and above) provides smoother and more reliable operation when receiver capacity is limited

Reliability Under Extreme Conditions

Robust and Reliable

Designed to perform at extreme temperatures

- From cold to hot and from dry to extremely humid conditions with design temperatures up to 115°F

- Optional outdoor modification and low ambient designs available

Designed for Serviceability

Low Maintenance Costs

- Hinged panel design gives easy access

- Stainless control lines and O-ring flanged faces eliminates leaks

- Filtered cabinet extends component life

Advantages

Safety and Protection

EG Series compressors are designed to ensure the highest level of safety.

- High-Pressure Trip

- High-Temperature Trip

- Pressure Relief Valve

- Low Voltage Trip

- Single Phase Preventer

- Reverse Rotation Prevention

Best-in-class Warranty*

The EG Series offers lifetime air end warranty and a 5-year package warranty, ensuring customers receive best-in-class compressed air products along with industry leading warranty coverage. * Terms and Conditions Apply

Applications

AUTOMOTIVE

FOOD AND BEVERAGE

CEMENT

PACKAGING

MINING

AGRICULTURE

TEXTILE

CERAMIC